In a turbulent and hyper-connected world, where immediate news takes precedence over fundamental issues, we can sometimes feel dizzy. However, in the face of upheaval, it is the islands of stability and continuity that are reassuring: the idea that remains, the concept that endures, the thing that lasts over time. What is perennial then reveals its own specific value.

At Somater, an ETI with a family history, we are deeply attached to this long-term vision. Whether it is our own company, which we wish to preserve and advance, the environmental cause or society at large: it is the sustainability of the models that, in the long term, makes the difference.

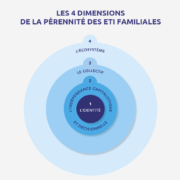

In this perspective, growth and profitabilitý are not ends in themselves, but means to another end: to be there tomorrow, in a better situation than today. We obviously share this observation with many companies. A recent study, carried out by Adrien Stratégie, has just identified the factors that condition the sustainability of ETIs. Four fields contribute to this, from the most limited to the most extensive: the identity, the capital and decision-making independence, the collective and the ecosystem. You can consult this study here.

We fully agree with the summary given in the preface by Alexandre Montay, General Delegate of the Mouvement des Entreprises de Taille Intermédiaire (METI): “No matter the weather. Good or bad, as long as it is long. Because seeing far ahead changes everything: social contract and links with employees, governance, local economic chain, business model performance, product positioning, growth profile, search for excellence and conquest. The economic model of the ETIs that this study deciphers […] is singular. Unfortunately, it is still too little known”.